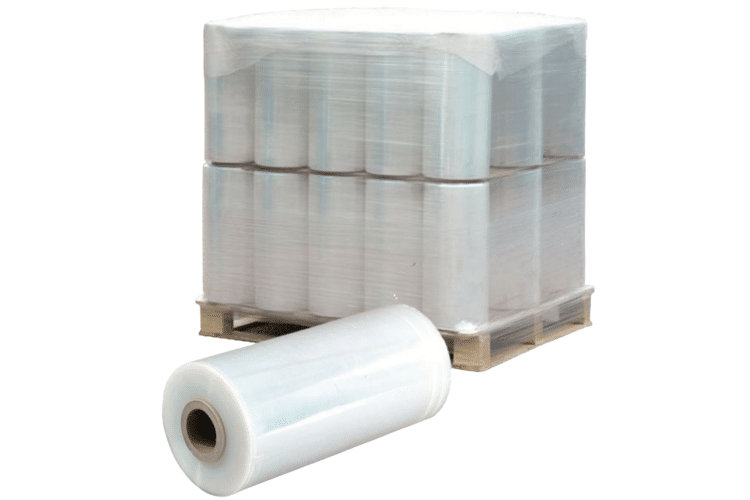

Cast Stretch Film

Cast stretch film is quiet and very clear. It has great transparency and resists tears and punctures. Excellent stretch properties with up to 250% stretch. Made from linear low-density polyethylene (LLDPE) resin, it prevents rupture and displacement during transportation. It is the ideal stretch film for protecting palletized goods.

What is cast stretch film?

Cast stretch film is made by pushing hot plastic through a flat die. It then cools on rollers. It is then wrapped around a core to achieve the desired effect and is suitable for both A and B load types. We offer hand film and machine film.

Features:

- Color: transparent, opaque, colored, black

- Thickness: 45–135 gauge

- Length: 4000–8000 ft

- Width: 20–30 inches

- Packaging: 4 rolls per carton

BestY, as a leading stretch film manufacturer and supplier, supports OEM and ODM custom production.

Product Details of bundling stretch film

- Protective: prevents dust, humidity, and moisture from invading the product. Offers excellent protection for products to satisfy your needs and your customers’.

- Quiet: Quiet and silent when unfolding, superior to the noise performance of blown film.

- High clarity: cast stretch film is highly visible and can be easily scanned electronically.

- Good fixation: It can easily fix the palletized package and will not shift during transportation.

- High puncture resistance: cast stretch film has excellent performance in puncture resistance.

- Uniformity: more uniform thickness than blown film.

Product Parameter Table of Cast Stretch Film

| Parameter | Specification/Description |

|---|---|

| Material | Linear Low-Density Polyethylene (LLDPE) |

| Production Process | Cast Extrusion, 3-7 layer co-extrusion |

| Thickness | 45-95 gauge (8-35 microns) |

| Width | 2-30 inches (50-750 mm) |

| Length | 100-2000 meters |

| Color | Clear, Black, White, Colored |

| Core Type | Plastic core |

Performance table of cast stretch film

| Performance Indicator | Test Standard/Data |

|---|---|

| Transparency | ASTM D1003, >90% |

| Tensile Strength | ASTM D882, 20-40 MPa |

| Elongation at Break | 250-300% |

| Puncture Resistance | ASTM D1709, 150-300 g |

| Tear Resistance | ASTM D1922, 400-600 g/mil |

| Thickness Uniformity | ±5% variation |

| UV Resistance | ASTM D4329, 6-12 months |

| Load Holding Capacity | 1.5-3 kg/cm² |

| Temperature Resistance | -20°C to 60°C |

| Coefficient of Friction | 0.2-0.4 (static) |