What is BOPP films?

BOPP film is a bi-oriented polypropylene film. Its unique manufacturing process allows it to undergo Transverse Stretching in both the longitudinal direction and the transverse direction. This makes BOPP film very strong and durable. It has a wide range of applications, from food packaging to product labeling. It has High transparency and good clarity. It is also very suitable for printing. It is suitable for use in a variety of flexible packaging applications. This includes pressure-sensitive tapes, labels, stationery, etc.

BOPP Film Properties

The unique production process of BOPP film gives it many unique properties.

- High transparency and clarity:

BOPP films have an excellent and Glossy appearance. It can show the packaging products and printed content very well. - Excellent barrier properties:

BOPP film can effectively isolate oxygen, moisture, and contaminants. It can protect the product from contamination and moisture. - Excellent Machine Performance:

BOPP Film Performance is excellent in puncture and tear resistance. It can protect the products well in a wide range of temperatures, against breakage during transportation and handling. - Recyclable:

BOPP film can be recycled. It can reduce pollution and its impact on the environment. It is very important for companies pursuing sustainable development. - Easy to seal:

BOPP film has a high heat sealing efficiency. It allows for fast and safe Heat sealing of packages. Very important in the food industry. It can effectively ensure food freshness and prevent contamination.

Types of BOPP films

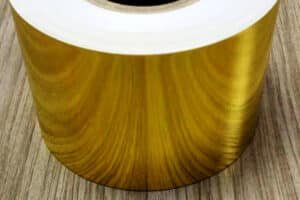

Metallized BOPP Films:

It is a BOPP film coated with a thin layer of metal. Usually, aluminum metal. This film retains its original toughness and low density. At the same time, it has new properties. It reduces the permeability to external factors. It can act as a good barrier. Prevents contact between the product and the environment.

Applications: Metallized Film is mainly used for packaging snacks and baked goods. It allows for high-quality printing and processing. It can be used as a single-layer film or as a laminated film. The applications are very wide.

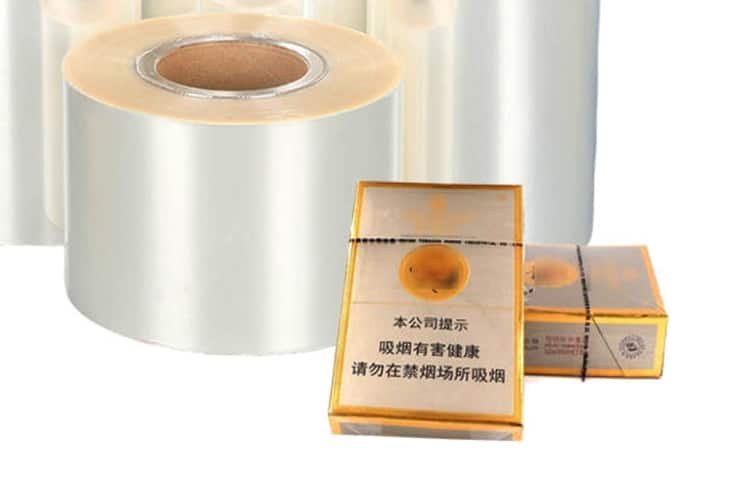

Heat-sealable BOPP film:

Its heat-sealing performance is even better. It can form a stronger seal when heated.

Application: Heat-sealable BOPP film is widely used in the printing of food and non-food packaging. It has double-sided heat-sealing properties. It can be used to package envelopes, candies, chewing gum, lozenges, cigarette cases, etc.

BOPP Glossy Film:

Its transparency and Glossiness are very good. It can be very clear to see the packaged products. Enhance the beauty of the package. It is also suitable for high-quality printing. Can print complex and clear patterns. The effect is clearer and beautiful.

Applications: BOPP Glossy Film is widely used in cigarette packaging and printing operations.

BOPP Matte Film:

BOPP Matte Film has a Matte finish. It is suitable for packaging scenarios where reflections and glare need to be minimized. It has a corona-treated inner layer and a matte, non-glossy outer layer. It has excellent printability. The surface is smooth and has a matte texture. It gives the appearance of higher quality.

Application: BOPP Matte Film is widely used. It can be used to package cosmetics, food, beverage boxes, book covers, and so on.

Anti-fog BOPP films:

A special anti-fog agent is added during production, which can effectively prevent fogging. It can keep the clarity and transparency continuously. It can also extend the shelf life of food.

Applications: Widely used in food and vegetable packaging, fruit, and meat packaging.

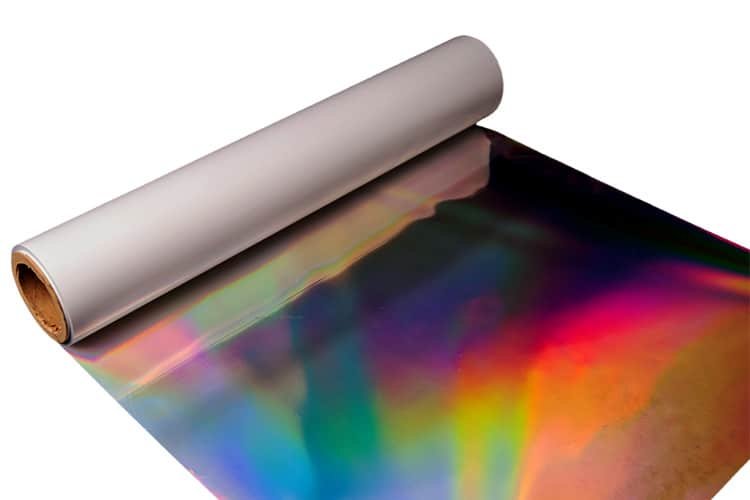

BOPP Holographic Film:

Its visual effect is more shocking. It can achieve a holographic effect. Improve the visual effect and recognition of products. It has excellent tear resistance, durability, and stability. It can also be customized with different patterns.

Applications: BOPP Holographic Film can be used to make anti-counterfeiting labels and packaging. It can also be used for liquor gift boxes, cigarette boxes, cosmetics, beverages, and other high-grade packaging.

BOPP Pearlescent Film:

It is like a pearl, a milky white BOPP film. It has a very good visual effect and can enhance the aesthetics of packaging. It has good Glossiness and a pearlescent effect. Printability is also excellent. High reflectivity, too.

Applications: It can be used for food and medical device packaging. It can also be laminated with other substrates for printing. Suitable for high-end food packaging. It plays a very good decorative role.

Benefits of Using BOPP Film

BOPP film is used in a wide range of applications, in industry, consumer goods, and food. It has many benefits.

- Variety of sizes: BOPP films are available in a wide range of sizes and can be customized according to different packaging needs. It can be well adapted to the different shapes and sizes of products from various ministries.

- Good durability: BOPP film has better chemical resistance. It can be in direct contact with chemicals for a long time. Its unique bi-directional stretching process gives it excellent durability as well. It usually has a shelf life of 4-8 months.

- Recyclable: BOPP film can be recycled and reused. It allows businesses to reduce costs. It allows companies to pursue sustainable development.

- Stable: BOPP film has excellent barrier properties, which can protect the product well from moisture and oxygen. It can reduce the damage to the product from weather and other environmental factors during transportation or storage.

- High transparency and clarity: BOPP film has high transparency and is UV-resistant. You can clearly see what the packaged product items are. It can also attract the attention of users and consumers. Improve the influence and attraction of the brand.

Why BestY Pack?

BOPP film has a very good development trend in the future. In terms of sustainability. There will be breakthroughs in coating technology innovation and new applications, etc.

The development of BOPP Film Performance coating technology can effectively improve the High Barrier Property and increase machine strength. Specialized coatings can allow BOPP film to be used in more areas. Such as the pharmaceutical and cosmetic fields. BOPP film is recyclable, but currently not degradable. The research and development of biodegradable BOPP film is crucial for environmental protection. We are a professional BOPP film supplier. If you are interested in our products, please contact us immediately!

Is BOPP film recyclable?

BOPP film is not biodegradable, but it is environmentally friendly. It can be recycled and reused many times. This reduces waste and is more cost-effective. There is also less pollution and impact on the environment. Now there are professional recycling machines suitable for recycling BOPP film. Operation and maintenance are simple. Excellent BOPP pellets can be produced after the recycling process.

Related Product

Related Blog

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351