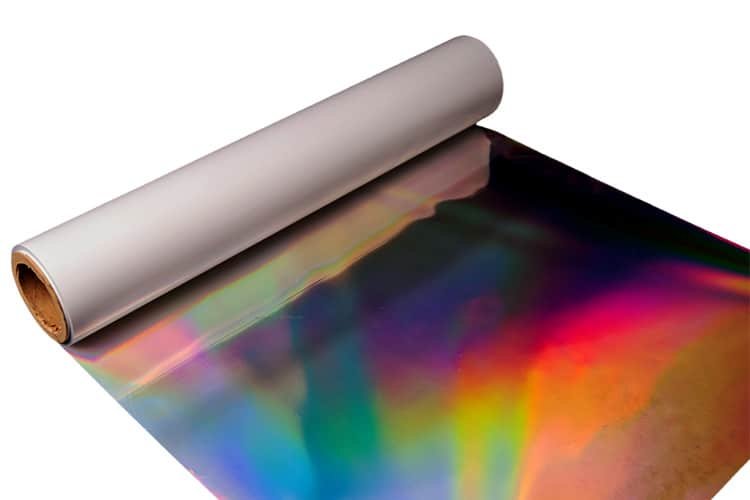

What is shrink film?

Shrink film is a very common plastic packaging material. It is made from a versatile polymer, usually POF(Polyolefin shrink film), PVC, or PE, which shrinks tightly when heated and then covers the product tightly.

Manufacturing process: The production of shrink film usually involves a six-step process. The first step is polymerization. In which ethylene is polymerized under high temperature and pressure or with a catalyst to obtain polyethylene. The polyethylene is then extruded through a die in a molten state. Films can be formed in monolayer or multilayer structures. Shrink films with different structures will have different properties. The third step is cooling. The extruded film is cooled and cured. The fourth step is Orientation, where the film is Transverse Stretching in both longitudinal directions. Bi-directional stretching changes the structure of the shrink film. It gives the shrink film better strength and transparency. The fifth step is to reheat the shrink film to a specific temperature and then cool it to set the shape. Finally, the film is cut to the required width and wound into rolls.

Application: Shrink film is mainly used for product packaging; it can be used to package food, cosmetics, electronic products, books, and so on. It has good transparency and tear resistance and can provide good protection. It is also used in the industrial and construction fields.

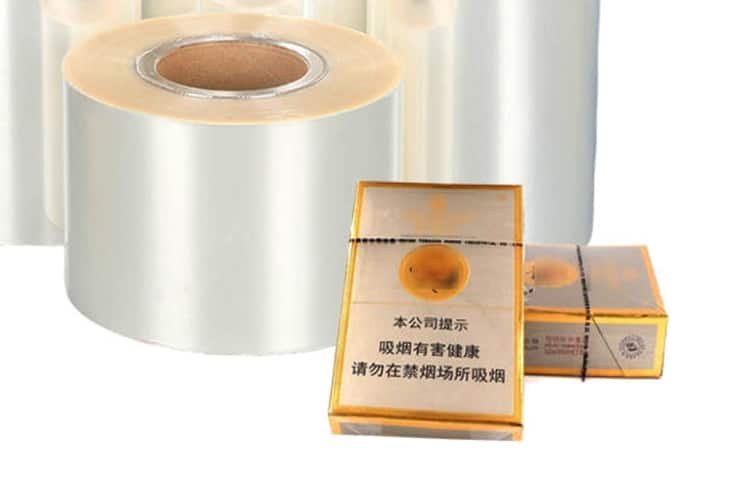

What is BOPP film?

BOPP film is a bi-oriented polyethylene film. It has excellent durability and strength. It also has very good transparency.

Manufacturing process:

The raw material is first fed into the extruders. The raw material is heated to a molten state of 210-235°C and extruded to form a foil. The foil is then fed to the Chill rolls and immersed in water for cooling. Next, the film is Transverse and Longitudinal Stretching in the machine. Finally, it is either treated or flame-treated. Depending on the requirements, the surface can be processed in different ways.

Application:

BOPP Film Performance is excellent and is widely used in various industries. In the food packaging industry, it can be used to package food and beverages. It has excellent clarity and transparency and is also suitable for labeling. The surface is smooth and suitable for printing. Its high strength High Barrier Property is also used to package medical supplies.

Shrink Film vs BOPP Film: A Comparison

Similarities:

Shrink and BOPP films are both made from polypropylene polymers. They have High transparency and can display products well. Good barrier properties. It can isolate water vapor and oxygen well. Stable and durable.

Differences:

Shrink film shrinks when heated and tightly wraps the product. BOPP film is bi-directionally stretched during production, with high strength, tear resistance and toughness . BOPP film has excellent thermal stability and will not shrink.

Shrink film is suitable for use in single products that need to be tightly wrapped. For example, CDs, etc. BOPP films are used more in areas such as food and snacks.

BOPP film has better tear resistance, stretch resistance, and shrinkage resistance than shrink film. BOPP film does not shrink under heated conditions and can be used for precise and complex printing needs. Shrink film shrinks when heated. So you need to calculate the amount of shrink film to be used in advance when packaging products.

Price difference:

Shrink film is cheaper for the same thickness.Less initial investment. But BOPP film has high strength and good protection, which can reduce the risk of damage during transportation. BOPP film may be more economically beneficial in the long run.

Environmental impact:

BOPP film can be recycled. Shrink film contains PVC, which releases chlorine gas when burned, which is more polluting to the environment. Neither of them is biodegradable. However, today the industry has introduced biodegradable BOPP. BOPP films are more environmentally friendly.

How to choose shrink film and BOPP film

When choosing between shrink film and BOPP film, you need to understand the specific needs.

- Product Characteristics: You need to choose the product characteristics. Fragile products give priority to shrink film. It has better puncture resistance and can better protect the product. If the product is sensitive to temperature and will be deformed and discolored in a heated environment, then you need to choose BOPP film. If you want a better display of appearance and Glossiness, you can choose BOPP film.

- Durability: Shrink film is excellent in durability, tear resistance, and impact resistance. Suitable for long-distance transportation and heavy items scenarios. BOPP film has higher tensile strength and is more suitable for items that need to be tightly bundled.

- Barrier property: BOPP film has better barrier property, can effectively isolate oxygen and water vapor. It can extend the shelf life of food.

- Sustainability: BOPP film is recyclable, and new biodegradable categories are now available. BOPP film is more environmentally friendly than shrink film.

FAQ

What is the difference between shrink wrap and plastic wrap?

Shrink wrap and cling film can both be used to wrap products. Although they are both made of plastic. But there are differences, and they are also used in different scenarios.

Shrink wrap film can be used to wrap anything, while cling film can only be used to wrap food, Fresh Produce, etc., in most cases. But shrink wrap shrinks only when it is heated. The shrink wrap needs to be wrapped around the product first and then heated with a Heat Gun or a hair dryer. Then the shrink wrap will shrink. Cling film, on the other hand, can be directly adhered to and wrapped around the product. It can usually be wrapped directly by hand.

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351