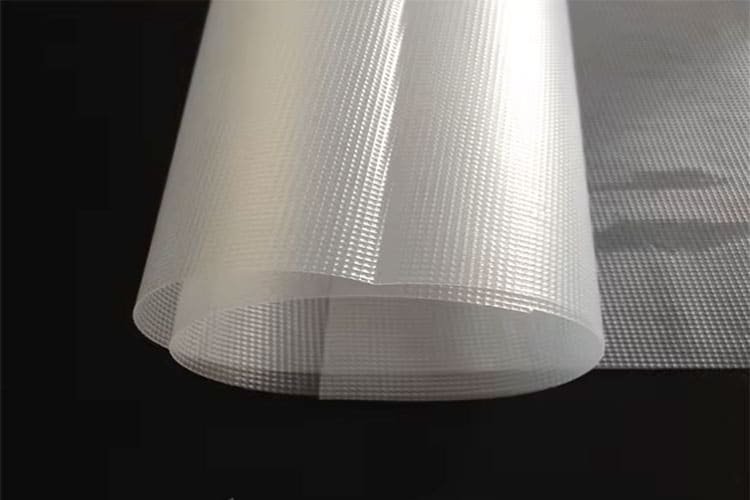

PVA Shrink Film Water Soluble Shrink Film

Water-soluble PVA shrink film melts in water. In cold water, it dissolves in 10 to 70 seconds. It leaves no residue or toxic substances behind. It represents the perfect eco-friendly solution for shrink packaging. This film is manufactured through the blown process using water-soluble polyvinyl alcohol. When heated to 240°C, it tightly shrinks to envelop the product. Dissolves in water. Cold water takes 10 to 70 seconds to dissolve, leaving no residue or toxins.

We are a film manufacturer from China with years of industry experience. Our factory features a complete production line and a professional design team. You can choose from various styles and specifications. We offer both OEM and ODM production options.

Features:

- Thickness: 10–100 μm, customizable

- Dissolution time (s): 10–70

- Fully biodegradable, compliant with the EU EN13432 standard, and no environmental pollution.

- Providing customized production services

Support OEM and ODM customization, please contact our experts

Product Details of PVA Shrink Film

Heat-shrinkable PVA water-soluble film is used widely in daily life. One common use is for packaging dishwasher tablets. This film has many features. Its clear look highlights products and boosts brand value. As environmental demands grow, green packaging is increasingly becoming mainstream. This heat-shrinkable PVA water soluble film serves as a biodegradable, eco-friendly packaging solution. It dissolves rapidly in cold water without leaving any residue.

As packaging, this film provides a quick and efficient solution. It offers strong sealing performance in dry environments, preventing product contact with skin. Our film shrinks at 240°C, tightly enveloping products. With a heat sealing strength of 2.5N/15mm meeting ASTM F88 standards, it ensures a secure seal.

As a professional film manufacturer, we provide OEM and ODM production services. Years of industry experience have earned BestY Pack a large base of loyal partners. Need customized production services? Share your requirements with us, and we’ll respond quickly.

Product Parameters

| Thickness | 10~100μm, customizable |

| Length | 90~2200m, customizable |

| Width | 300~600mm |

| Material | PVA |

| Processing Type | Blow Molding |

| Color | Transparent |

| Printing | Gravure |

| Core Diameter | 3” / 6”, customizable |

| Certification | ISO9001 |

| Production Method | OEM/ODM |

| Transportation Method | Pallet Transportation |

| Shipping Port | Shanghai Port, Guangzhou Port, Hong Kong Port |

Technical Parameters

| Dissolution Temperature (°C) | <25 |

| Disintegration Time (s) | ≤25 |

| Dissolution Time (s) | 10~70 |

| Tear Strength (kN/m) | ≥85 |

| Tensile Strength (MPa) | ≥28 |

| Elongation Rate (%) | ≥110 |

| Shrinkage Temperature (°C) | ≥240 |

| Shrinkage Rate (%) | ≥45 |

Why Choose BestY Pack?

We are a PVA water-soluble film manufacturer from China, offering a wide range of film styles. We focus on film and packaging production and R&D. Our skilled film development team is led by industry experts. With years of market experience, we innovate film types based on customer needs. We provide customized solutions tailored to meet your production and packaging requirements.

- Our skilled team quickly creates custom production solutions for your unique needs.

- We have years of export trade experience. So, we handle international logistics smoothly for easy, hassle-free shipping.

- We are a trusted manufacturer known for positive reviews and loyal customers.

- Cost-effective and high-value, our film products deliver exceptional quality at competitive prices.

Advantages

Application

Heat-shrinkable PVA water-soluble film can be applied in various scenarios, including household and daily chemical products, food packaging, and the pharmaceutical industry.

Household

Commonly used for packaging cleaning products, reducing direct operator contact, and enhancing production efficiency. Examples include detergent packaging, solid tablet dishwashing liquid packaging, and dishwasher tablet packaging.

Food

This film is safe and non-toxic, allowing direct food contact. Examples include: effervescent tablet packaging.

Pharmaceuticals

The film is hygienic and meets medical-grade contact standards. Examples include: single-dose medication packaging.