Plastic films are widely used across various industries, serving diverse functions. Their applications span from food packaging to protecting medical supplies. Flexibility, durability, and cost-effectiveness have long been among their many advantages. The rapid growth of modern society is driving up the demand for sustainable packaging. This trend is now well established. Consequently, different types of plastic films have been developed to meet customized needs. In this blog, we will explore the types, properties, and application areas of plastic films. This guide will provide valuable insights to assist you in making informed choices.

What is Plastic Film?

Plastic film is a lightweight polymer used in many industries. Its versatility and benefits make it a popular choice. Its manufacturing process starts by extruding hot plastic through a die. This creates a thin coating. Then, it cools and gets wound into rolls. It comes in clear and opaque types. You can also adjust the thickness and length to fit your needs.

Key Characteristics and Advantages of Plastic Films

- Flexibility: They can be molded into various shapes, are adaptable to different application needs, and offer versatile formability.

- Durability: Highly resistant to abrasion and tearing, making it ideal for protective packaging.

- Sealing Performance: Excellent sealing properties effectively block air, providing moisture resistance, oxidation protection, and contamination prevention.

- Cost-Effectiveness: Lightweight and efficient, it represents a cost-effective packaging solution.

- Transparency: Most films are transparent, allowing direct visibility of packaged products and enhancing sales appeal.

Common Applications of Plastic Film

Plastic film is widely used across various industries. Some common applications include:

- Electronics Industry: Plastic film is extensively used in the electronics industry to protect sensitive electronic components from electrostatic damage during production.

- Agricultural Applications: In agriculture, plastic film is primarily used for greenhouse covering, providing crops with optimal growing temperatures.

- Medical Supplies: In healthcare, plastic films are primarily used to package medical supplies, ensuring cleanliness and hygiene before use.

- Food packaging: Plastic films are extensively used to protect food packaging, such as for fresh meats and snacks. Their great moisture resistance keeps products safe from contamination, which helps them last longer.

- Industrial Applications: They serve as protective layers or composite material components in manufacturing.

Understanding the various types of plastic films and their specific functions helps businesses select the most suitable material for their needs.

Different Types of Plastic Films

Due to their superior properties, plastic films are widely used across various industries. The following section will detail different types of plastic films and their applications.

PVA-Coated High-Barrier Film

PVA-coated high-barrier film comes from coating polyethylene film with PVA and tiny materials. It’s economical and offers great isolation from outside elements. It’s often used for packaging milk, drinks, and vinegar. Its superior barrier properties make it an ideal solution for addressing aseptic packaging challenges.

Biaxially Oriented Polypropylene Film (BOPP)

BOPP film is produced by co-extruding polypropylene and stretching it both horizontally and vertically. This process yields excellent physical stability, gas barrier properties, and outstanding transparency and gloss.

Low-Density Polyethylene Film (LDPE)

LDPE film is typically manufactured using blown or cast film processes. It features a semi-transparent, glossy surface and excels in water resistance, heat sealability, and chemical stability. It is frequently used for food packaging. Its main drawbacks are relatively poor sealing properties and limited oxidation resistance.

Polyester film (PET)

PET is made from polyethylene terephthalate. Due to its resistance to high and low temperatures, excellent printability, outstanding hardness, and superior puncture resistance and mechanical properties, it is used as an outer layer material for retort packaging.

Nylon Film (PA)

Nylon film is transparent, tear-resistant, withstands extreme temperatures, offers good oxygen barrier properties, and is oil-resistant. It is commonly used for fried foods and vacuum packaging. However, its drawbacks include high moisture permeability and poor vapor barrier performance.

Cast Polypropylene Film (CPP)

CPP film, made from polypropylene, is transparent with excellent heat-sealing properties. It comes in standard and retort grades and is commonly used for gift and meat packaging.

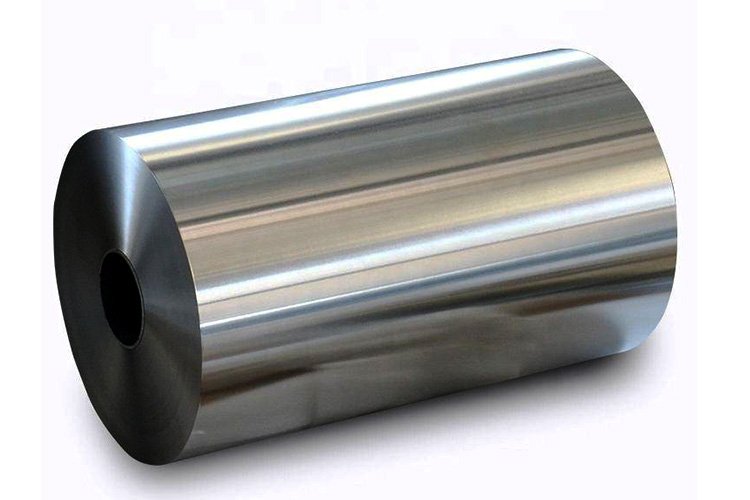

Metallized Film

Metallized film combines the properties of metal and plastic, offering UV resistance to enhance packaging gloss and extend product shelf life. It is frequently used in composite packaging and has largely replaced aluminum foil due to its cost-effectiveness and aesthetic appeal.

Applications for Different Types of Plastic Films

The following section provides a comparative analysis of plastic films to help you gain a deeper understanding and select the most suitable type for your needs.

| Plastic Film Type | Common Uses |

|---|---|

| PVA Coated High Barrier Film | Beverages, milk, vinegar |

| Biaxially Oriented Polypropylene Film (BOPP) | Printing, packaging, outer layer of composite films |

| Low Density Polyethylene Film (LDPE) | Food packaging, inner layer of composite flexible packaging |

| Polyester Film (PET) | Retort packaging, high-temperature packaging Printing, packaging, outer layer of composite films Meat products, fried foods, vacuum packaging |

| Cast Polypropylene Film (CPP) | Gift packaging, high-temperature cooking applications |

| Metallized Film | Alternative to aluminum foil, aesthetic packaging |

Comparative Analysis of Plastic Films

The following section provides a comparative analysis of plastic films to help you gain a deeper understanding and select the most suitable type for your needs.

| Plastic Film Type | Advantages | Weaknesses | Ideal Applications |

|---|---|---|---|

| PVA Coated High Barrier Film | Excellent barrier properties | Narrow application range | Beverages, juices, milk, soy sauce, vinegar |

| Biaxially Oriented Polypropylene Film (BOPP) | High transparency, mechanical strength, gas tightness | Poor heat sealability | Printing, outer layer of composite films, packaging |

| Low Density Polyethylene Film (LDPE) | Chemical stability, heat sealability, moisture resistance | Poor oxygen barrier | Food packaging, inner layer of composite packaging |

| Polyester Film (PET) | High rigidity, toughness, puncture resistance | Higher cost | Retort packaging, high-temperature applications |

| Nylon Film (PA) | High tensile strength, good oxygen barrier | High moisture permeability | Oily foods, meat products, vacuum packaging |

| Cast Polypropylene Film (CPP) | Excellent transparency, good heat sealability | Lower mechanical strength | Gift packaging, meat packaging, cooking applications |

| Metallized Film | UV protection, extended shelf life, aesthetic | Lower flexibility | Composite packaging, alternative to aluminum foil |

BestY Pack

Choosing can be tough because there are many types and performance features. Consult BestY Pack. We will choose the best plastic film for you. This ensures your products are reliably packaged.

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351