What is PET film?

PET film is a thermoplastic film. It is made from polyethylene terephthalate. It has very good thermal stability. It can withstand a wide range of temperatures. It can withstand temperatures as low as -68°C (-90.4°F) and as high as 145°C (293°F). PET film is also one of the most environmentally friendly Thermoplastic packages available. There are three main production processes for PET film: the Stretching Process, Extruding Process, and Coating Process. The unique production process and the characteristics of raw materials make PET Film Performance very good. Its physical properties and chemical stability are excellent. It has a wide range of applications.

PET film characteristics and advantages

PET Film Performance has excellent properties due to the unique manufacturing process.

Machine Performance: PET Film Performance is excellent in terms of tear resistance and tensile properties. Robust and durable. It can withstand various environmental conditions. It can effectively protect products during transportation, handling, and storage, and can extend product shelf life. PET film’s thermal stability is also very good, and it can also effectively protect the product. PET film’s airtightness is also very good, and it can effectively isolate oxygen and moisture. In the field of food packaging, it can prevent food from rotting and spoiling and reduce waste. Extend the shelf life.

Transparency: The transparency and Glossiness of the PET film are also very good. You can see the packaged products very clearly. Very suitable for packaging beverages and food.Personal products, cosmetics, and so on. It can enhance the attractiveness of the product to users and customers.

Environmentally friendly and recyclable: PET film can be recycled and reused. It can reduce waste. It is currently one of the representatives of sustainable plastic packaging materials. It is very important for companies to pursue sustainability. It is about 82% sustainable. It can be recycled about 6-8 times before degradation. It can greatly reduce the cost of the business.

Common PET applications

- Food industry: PET films have excellent barrier properties. It can isolate oxygen and moisture very effectively. Protects food from oxygen, moisture, and other contaminants. It can extend the shelf life of food. Reduce waste. Can be used to package fruits, meats, snacks, desserts, and more. PET film is very popular in the food packaging industry and is also an FDA-approved food safety packaging material.

- Pharmaceuticals: PET film can also be used to package medicines and medical devices. It prevents dust from contaminating medicines and equipment. PET film has excellent chemical resistance. It will not be affected by medicines and will not affect them.

- Electrical and electronic: PET film also has excellent insulating properties. It can be used to package wires and cables. PET film insulation can protect wires and cables from damage. PET film has excellent heat resistance. Electronic circuits are related to electricity, heat, and friction, and PET film will not affect the electronic circuits. It can also be used to produce pressure-sensitive labels,

- Other areas: PET Film Performance is excellent for printing. It can be used for printing. It can be used to print complex patterns with excellent clarity. PET film can also be used to package trays, Blister Packaging. PET film is non-reactive in itself; it can be mixed with other raw materials to make different compounds and packaging materials.

Types of PET Film

There are many types of PET films with different characteristics. They are used in different fields and scenarios. PET films can be categorized into two main groups according to their functions: general-purpose PET films and functional PET films.

- General-purpose PET film: the most common standard PET film. No coating is added. It has High transparency and good Glossiness. It has chemical resistance. Commonly used in food packaging and printing.

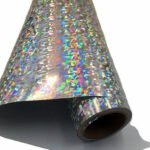

- PET high-gloss film: PET high-gloss film has even better optical properties. It has good transparency. Low haze, high Glossiness. It can be used to make vacuum aluminized products. It can also be used for laser anti-counterfeiting film.

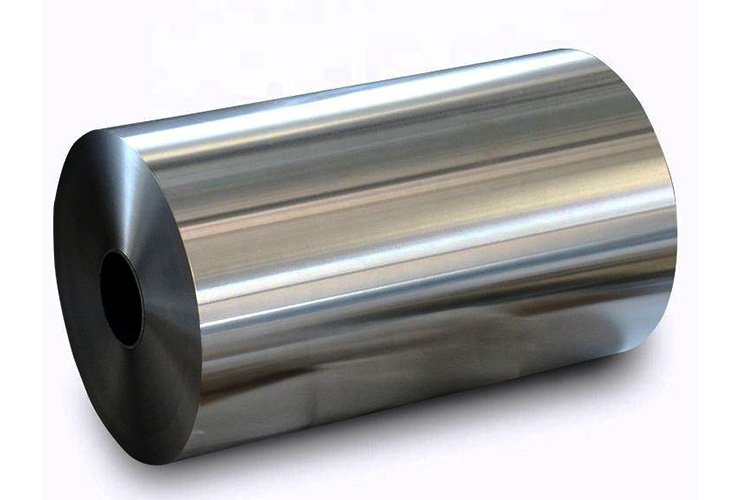

- Metallized Film PET: Metallized Film PET is a specially treated plastic film. It has a layer of metallic aluminum particles on its surface. Metallized Film PET has excellent physical, optical, thermal, electrical, and chemical properties. Its reflectivity will also be higher. The optical density (OD) of PET metallized Film usually ranges from 0.22 to 3.2. The higher the optical density, the lower the transparency. It will also have a different electrical conductivity. It can also be used to package microwaveable dishes with low water content, etc. It can allow food to absorb heat more quickly. It allows the food to absorb heat and heat up more quickly.

- PET release film: The PET release film is coated with silica gel on the surface of the PET film. Its surface is smooth and even. It can effectively avoid wrinkles, bubbles, particles, and other defects of the film. It has excellent physical properties. High transparency, low heat shrinkage, good plasticity.PET release film is commonly used as a carrier for vacuum aluminum plating. It is also commonly used in wrapping goods, printing, sealing materials, and other industries.

FAQ

What is the difference between DTF film and PET film?

DTF film is a special kind of PET film. It is mainly used for transfer printing, where the design is first printed on the DTF film and then transferred to other textiles by heat and pressure. The pattern is then transferred to other textiles by heat and pressure. DTF film has a unique coating that is suitable for printing. DTF film is made by a unique coating process. It absorbs the ink better and also separates the pattern from the film very easily and cleanly. Ordinary PET film does not have these properties.

Related Products

Related Blog

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351