BOPP film holds over 30% of the global flexible packaging market share, making it a critical material. Drawing on 15 years of industry experience, this article provides a detailed explanation of BOPP film to assist you in material selection.

What is BOPP film?

BOPP film is a plastic film manufactured from polypropylene, commonly utilized for packaging, labeling, and lamination. Produced via Ziegler-Natta catalytic polymerization, polypropylene exhibits exceptional flexibility (elongation >200%) and adapts well to complex surfaces, making it an ideal packaging substrate.

BOPP undergoes biaxial orientation (MD/TD ratio 3:1), enhancing strength by over 30% and significantly outperforming uniaxially oriented films. BOPP film is unrivaled in both visual appearance and mechanical and physical properties.

What are the characteristics of BOPP film?

BOPP film boasts comprehensive properties, making it highly valued within the packaging industry. Its principal characteristics include:

Optical Properties

BOPP film exhibits transparency >90% and gloss >85 GU, enhancing product presentation and consumer appeal.

Mechanical Properties

High Strength: BOPP film is robust and durable, exhibiting strong puncture and tear resistance. It remains intact during transit, providing reliable product protection.

Elongation: Elongation exceeds 400%, ensuring durability under high tensile forces (> 50 N/mm).

Abrasion Resistance: BOPP film exhibits excellent wear resistance, prolonging the longevity of product protection.

Electrical and Chemical Properties

Anti-Static Performance: Low electrical charge accumulation prevents static buildup, effectively repelling dust and maintaining surface cleanliness.

Chemical Resistance: Withstands corrosion from most acids, alkalis, and oily substances, preserving physical properties across diverse environments to ensure packaging integrity.

Barrier and Preservation Properties

Moisture and Water Resistance: BOPP film serves as an excellent moisture barrier, suitable for packaging moisture-sensitive products such as soda crackers and preserving food textures.

Gas Barrier Properties: BOPP film exhibits moderate oxygen barrier properties, which can be significantly enhanced through specialized treatments. Common treatments include metallized film and acrylic coating. These effectively prevent product oxidation, extending shelf life.

Varieties and Applications of BOPP Film

Clear BOPP Film:

The most commonly used base variant is clear BOPP film. This type offers excellent processability, enabling diverse processing according to specific requirements: WVTR < 5 g/m²·day, and a water barrier layer combined with pressure-sensitive labels for ink protection.

Applications: Food packaging, printed packaging, retail packaging

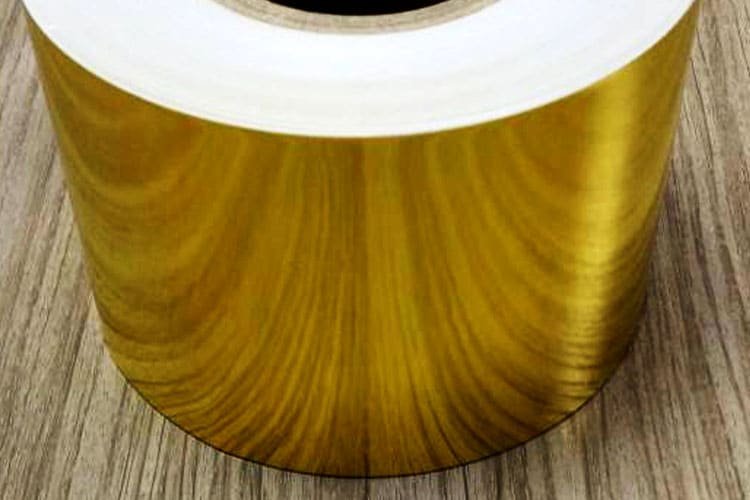

Metallized BOPP Film:

Metallized BOPP film employs vacuum metalization technology to deposit a metallic layer onto the BOPP surface. It possesses properties similar to aluminum foil, offering strong barrier properties and reflectivity, yet with greater cost-effectiveness.

Applications: Confectionery packaging, gift box packaging, pharmaceutical tablet packaging

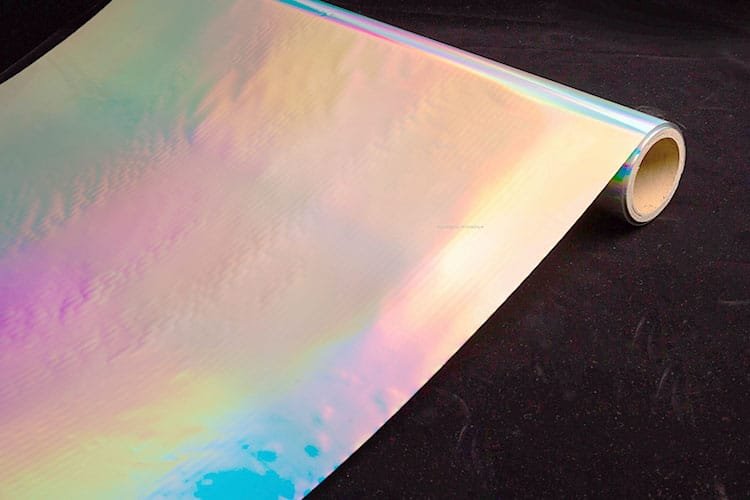

Holographic BOPP Film:

Holographic BOPP film offers excellent visual appeal and is manufactured from thermoplastic material. Available in transparent and opaque variants, it features holographic iridescent effects.

Applications: Cigarettes, cosmetics, anti-counterfeiting labels, decorative items

Heat-Sealable BOPP Film:

This variant of BOPP film offers excellent stretch moldability and printability. It provides strong sealing properties and is suitable for thermal lamination.

Applications: Face mask packaging, snack packaging

Pearl-Finish BOPP Film:

Pearl films are typically white and opaque, offering light-blocking properties and a pearlescent effect. They effectively block a portion of light.

Applications: Ice cream packaging, chocolate packaging, beverage bottle labels

BOPP Matte Film:

BOPP matte film carries a higher cost but enhances print quality by absorbing and reflecting light, though it lacks a heat-seal layer.

Applications: Luxury goods packaging, food packaging

Printable BOPP Film:

Printable BOPP film offers strong visual appeal with high gloss. Ink adheres strongly, enabling the printing of distinctive patterns and designs on packaging.

Applications: snack packaging, advertising posters

Anti-fog BOPP Film:

Anti-fog BOPP film incorporates anti-fog additives in its formulation, maintaining clear visibility even under significant temperature differentials between interior and exterior environments.

Applications: Fresh produce packaging, convenience store ready-meal packaging.

The Future Development of BOPP Film

Environmental Sustainability:

BOPP film currently meets recyclability standards. With a recycling rate exceeding 95% and compatibility with PP, the process is straightforward. Manufacturers are further optimizing BOPP film’s recyclability through innovative design.

Technological Innovation and Performance Enhancement:

The production and R&D of BOPP film are integrated with new technologies, significantly improving barrier properties and mechanical performance.

Expanding Application Domains:

BOPP film applications are progressively broadening within the cosmetics and medical sectors, with performance standards increasingly meeting market demands.

BestY Pack

We are a specialist BOPP film manufacturer in China, committed to sharing our expertise to assist you in making informed choices. With extensive experience in the production and distribution of flexible packaging, we maintain close partnerships with clients across multiple countries. We collaborate to design satisfactory packaging solutions that deliver superior quality at competitive prices.

We offer bespoke production capabilities. Whether regarding packaging dimensions, thickness, processing methods, or performance requirements, we can accommodate your specifications. Should you require our services, please contact us promptly. Our expert team will assist you at the earliest opportunity.

FAQ

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351