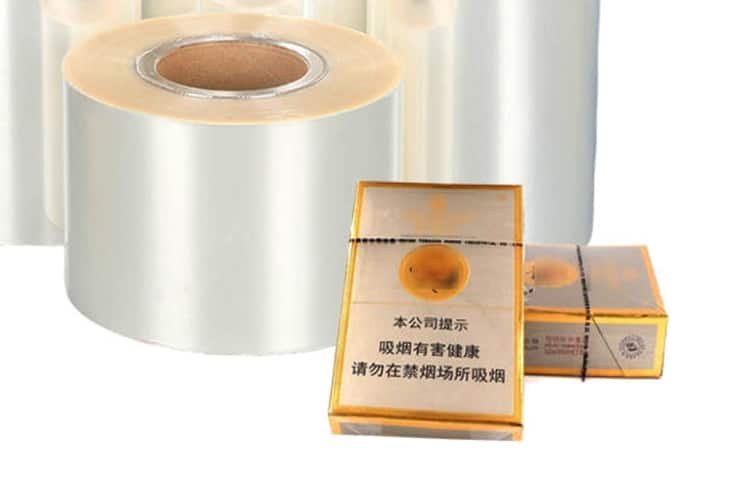

Clear/Transparent BOPP film

Transparent BOPP film is a popular material for plastic labels. A biaxially oriented polypropylene process produces it. It is coated with acrylic and is available in single-sided and double-sided coatings. It has ultra-high transparency, excellent physical properties, and environmentally friendly characteristics. It is widely used for labels that are self-adhesive or pressure-sensitive. This includes labels for beverages, wine, personal care products, food, and cosmetics. It is an ideal choice for the modern packaging industry.

Features:

- High transparency

- Excellent ink adhesion

- Clear UV ink printing

- Easy to label, good flexibility

- Easy to peel, no bending

Product Details of descriptions

Biaxially oriented polypropylene film is a soft, clear film. It is made with a special biaxial stretching process. It can be used to produce a variety of personalized labels. Its high transparency and glossiness make it attractive for use in a wide range of industries. Transparent BOPP film is highly clear. It’s biaxially stretched in both the machine direction (MD) and transverse direction (TD). This tight arrangement cuts down on light scattering and gives it crystal clarity. It can be used for various product labels, making the product appear as if it has no label at all. It can improve the appearance.

BOPP film shines in UV flexographic printing. It creates clear patterns and barcodes. Plus, it can be easily laminated, with a low coefficient of friction (COF) down to 0.2. It has excellent strength and adhesion, as well as good corrosion resistance. Thus, it is one of the most popular label materials.

Product Advantages:

- Enhance brand image: Can enhance product appeal.

- Good printing performance: Suitable for UV ink, flexographic, and gravure printing, with clear patterns.

- Environmental advantages: Compliant with sustainable development requirements.

- Good heat sealing performance: suitable for high-speed production.

Customization Options:

You can choose between single-sided or double-sided polypropylene coating. The single-sided option can also be treated on the other side. Treatments include corona, PVDC, or PVOH coating.

| Item | Available Range | Description |

|---|---|---|

| Thickness | 15μm – 70μm | Standard options: 23μm, 45μm, 50μm, etc. |

| Width | 500mm – 2050mm | Standard widths: 1090mm, 1550mm, etc. |

| Length | 6000m – 12000m | Customizable based on requirements |

| Coating Type | Single-sided / Double-sided | Enhances printability & heat-sealing performance |

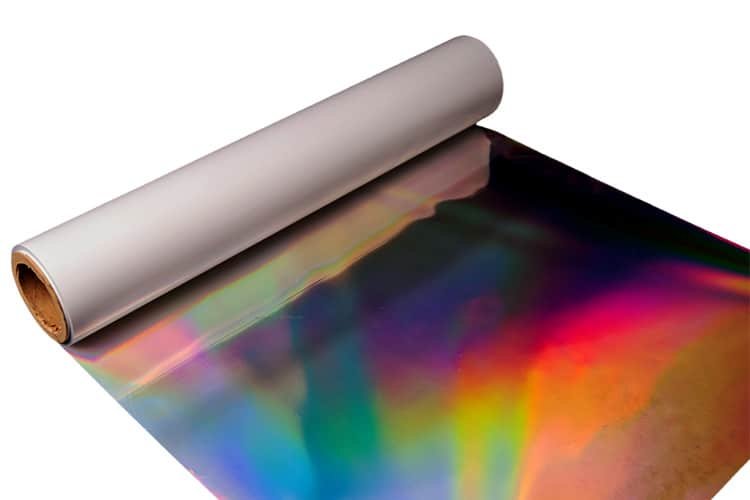

| Surface Finish | Glossy, Matte, Holographic, etc. | Meets different visual effect needs |

| Printing Method | Flexo, Gravure, Digital Printing | Supports various high-quality printing solutions |

| Special Features | Anti-static, UV-resistant, O₂-barrier, etc. | Functional film options for advanced applications |

Application:

Transparent BOPP film is suitable for labels on wine bottles, snacks, daily necessities, baked goods, fruit packaging, etc.