Lamination film is available in many materials and styles. It protects printed items and boosts their visual appeal. Used in retail, commercial, and catering sectors, it is a great long-term solution. This article explains lamination principles and the roles of different lamination films. It will help you choose the best option.

Introduction to Lamination Film

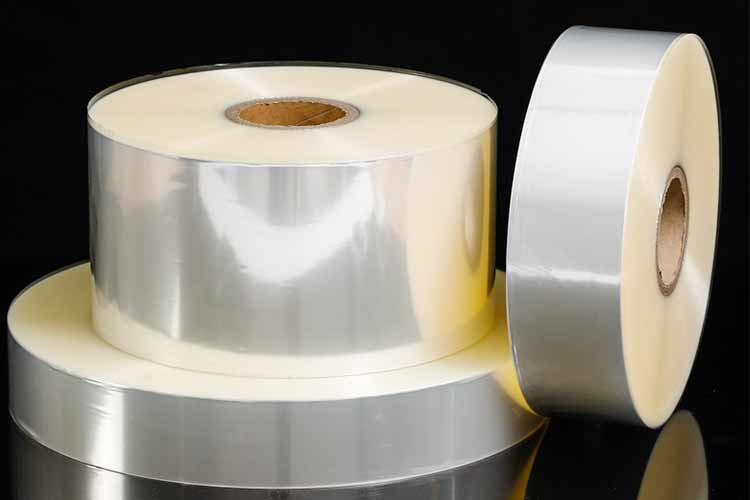

Lamination Film: What Is It?

Lamination film is specifically designed to protect printed materials. These films are available in many materials and are made using different methods. They offer protection and improve the appearance of cardboard, paper, and other printed surfaces. Applying a laminate layer offers moisture resistance, oxidation protection, and UV shielding. This significantly reduces the risk of damage to printed items and extends their service life.

Lamination film holds revolutionary significance in the sales, display, and advertising sectors. Simultaneously, it supports environmental sustainability by reducing resource wastage.

Lamination Film: Types, Characteristics & Applications

Lamination film comes in different types. This depends on the processing techniques and materials used. Below are common lamination film types, their characteristics, and application scenarios.

What Products Are Available for Lamination Film?

Thermal Laminating Film

Thermal Laminating Film Principle: Contains a heat-activated adhesive that melts when heated. Upon cooling, it forms a robust bond between the film and printed material.

Characteristics:

- Strong Adhesion: Utilizes a specialized hot-melt adhesive. Ensures the film adheres firmly to printed materials, becoming difficult to peel off once set.

- Excellent Sealing: Completely covers printed materials, providing waterproof, oil-resistant protection. Prevents liquid penetration and protects paper.

Applications:

Paper Documents: Provides essential protection for paper through robust adhesion and waterproofing. Commonly used in the catering and education sectors. Examples include:Menus, certificates of achievement, sales brochures, promotional leaflets, and book publishing

Outdoor Signage: Anti-UV properties slow fading from light. Waterproofing allows use in any weather. Examples include:Handheld advertising boards, class identification signs, and event promotional boards

Cold Lamination Film (Pressure-Sensitive Film)

Cold Lamination Film: This film uses Pressure-Sensitive Adhesive (PSA) on printed materials. Bonding is achieved through pressure, hence the name pressure-sensitive film. Popular products include OPP lamination film.

Features:

- Bonding without heating: Achieves adhesion without additional heat, suitable for heat-sensitive printed materials. Saves processing energy consumption, reducing costs to some extent.

- Strong sealing properties: Completely covers printed materials, providing a water- and oil-resistant barrier. Prevents liquid penetration, protecting paper.

- Customizable performance: You can adjust adhesive formulas to change the film’s properties. This affects initial tack, final adhesion strength, and resistance to environmental factors. These include temperature, humidity, and UV rays.

- Process simplification: Eliminates heating and cooling stages, significantly boosting production efficiency.

Applications:

- Heat-sensitive products: Cold lamination film bonds without heating, crucial for heat-intolerant items. Common examples include:

- Photographs, low-melting-point plastics, antique items.

- Cold lamination film benefits small printed materials. It cuts energy use, saves money, and boosts efficiency for small batches. Common examples include:

- Cultural and creative products, personal business cards, and small signage.

Specialized Lamination Film

Principle of Specialized Lamination Film: Specialized lamination film is tailored for specific applications. It achieves the right performance by using special coatings, unique processing, or special materials for specific uses.

Metalized Lamination Film

Principle of Metalized Lamination Film: Metalized lamination film uses vacuum deposition to coat its surface with a thin layer of metal.

Characteristics:

Superior sealing: Enhanced moisture resistance and oxygen barrier properties. The metal coating significantly boosts protective performance.

Sunlight blocking: The metal surface provides complete opacity, effectively shielding against sunlight.

Enhanced visual impact: The metal layer reflects over 80% of incoming light, providing a strong gloss. This enhances the packaging’s visual appeal.

Applications:

Cardboard packaging is moisture-resistant. This helps prevent dampness and makes it look better. Common applications include:

Cigarette packaging, chewing gum packaging

UV Lamination Film

UV Lamination Film uses UV inhibitors in its mix. This helps slow down fading and ink oxidation.

Characteristics:

- Anti-UV:The UV inhibitor keeps colors bright for a long time. It’s a great way to slow down color fading.

- High Transparency: This lamination film offers great visibility. It’s perfect for showcasing and protecting creative works and images.

- Low Sealing Temperature: Sealing doesn’t need high heat. This stops ink from degrading due to heat.

Applications:

- Photo Laminating: UV lamination film stops photos from fading. It keeps their colors bright for a long time.

- Printed Advertisements: UV lamination film protects printed materials and ads. It has strong anti-UV and waterproof features. It shields against fading caused by atmospheric moisture, oxygen, and light exposure.

The Visual Impact of Lamination on Printed Materials

Lamination not only extends the lifespan but also enhances the visual appeal of printed materials.

Aesthetic Appeal

Choosing different plastic films for lamination based on the application can create various visual effects. High-gloss and high-transparency finishes or matte and frosted effects can be achieved. Gloss lamination enhances color vibrancy, while matte lamination creates a softer appearance. It keeps ink colors bright, so printed materials look good for a long time.

Professionalism

Laminated printed materials convey a heightened sense of professionalism. They elevate tactile quality, making printed items stand out. This helps businesses create a superior impression on clients. Particularly suited for commercial applications such as marketing brochures and restaurant menus.

Laminating Helps You Build Wealth

Laminating Can Help Reduce Expenditure

Laminating helps printed materials last longer. This means you replace them less often, saving money. It provides excellent protection for printed items. Resistant to creasing and fading, it minimizes the risk of accidental damage. Materials remain as good as new even after multiple uses. This significantly reduces ink and material costs.

Lamination Boosts Revenue

Lamination not only elevates print quality but also showcases your corporate image. High-quality printed materials signal your company’s caliber to clients and partners. This enhances your corporate image, indirectly driving revenue growth.

When is lamination film used?

Lamination film is used in many sectors. Almost every industry relies on it. Lamination film is essential in many areas, like catering, commerce, industry, and entertainment. It provides crucial protective coatings.

- Applications of lamination film in the catering industry: Menus

Whether in small pubs or grand hotels, the catering trade requires menus. These serve not merely as a medium to present dishes to customers. Menus also reflect a restaurant’s taste, forming the customer’s first impression. Laminating film makes menus glossier. It helps food images look brighter and more appealing. - Applications of laminating film in education: Book covers, certificates

As frequently used learning tools, books require considerable durability. Thin paper alone cannot withstand high-frequency handling. Therefore, laminating film holds significant importance for textbooks. Certificates and awards are special keepsakes. They need to be durable and have a great texture for touch. Laminating film serves as an excellent solution. - Applications of laminating film in the commercial sector: Business cards, product brochures, leaflets, posters

Building a reputable enterprise hinges on creating a favorable first impression. Laminating film boosts the quality of printed materials. It’s perfect for promotional items. Think business cards, leaflets, product catalogs, and event posters. - Applications of lamination film in packaging: Cigarette packets, confectionery boxes, chewing gum wrappers

Paperboard packaging has some downsides. It can easily absorb moisture, and it often lacks visual appeal. Using lamination film not only improves packaging sealing but also enhances its aesthetic appeal. It protects against moisture and dust while enhancing the product’s visual appeal.

How should I select the appropriate lamination film?

Choosing the right lamination film involves considering several key factors, such as:

The dimensions, thickness, and material composition of the printed substrate

The size and thickness of the printed substrate determine the dimensions of the lamination film. The heat resistance of the printed substrate influences the choice of lamination film material. Heat-sensitive materials or inks need cold lamination film. This protects the printed substrate and ink patterns from damage.

Functional Requirements of the Application Scenario

The intended use of the printed material dictates the necessary properties of the lamination film. For humid areas, you need a water-resistant laminate. In high heat, both the film and adhesive need more heat resistance. For outdoor use, UV inhibitors must be included in the mix.

Visual Effect Requirements

Another factor to consider is the client’s aesthetic expectations for the printed material. Any externally displayed printed material may require enhanced visual appeal. Using a high-gloss lamination film on restaurant menus can boost buyer interest. But too much gloss in formal settings can hurt professionalism. Surface treatment requirements also warrant separate consideration.

Machine Compatibility

Lamination film application requires specialized machinery, which in turn requires corresponding equipment. For hot lamination films, controlling temperature during machine lamination is key. For cold lamination films, accurate pressure control matters most. Equipment compatibility forms the fundamental prerequisite for processing lamination films.

Other Considerations

Beyond the points above, numerous practical factors demand attention during implementation. Operational costs vary. Each lamination film has its own price, and machinery uses power differently. Sustainability also matters. Environmental protection now plays a big role in choosing packaging materials. Assessments must encompass recyclability and whether processing generates harmful emissions.

choose BestY Pack

Choosing the right lamination film can be tough for consumers looking for the best solution. BestY Pack offers a diverse range of lamination films through market research conducted by our specialist team. Our dedicated product design team provides bespoke production services. As China’s premier lamination film manufacturer, we supply high-quality lamination films.

We are dedicated to serving every client well. We provide custom lamination film production services that ensure satisfaction.

FAQ

What are the benefits of using lamination film?

Lamination film has many benefits. It’s low-cost and provides great value for money.

- Protective properties: A strong seal keeps moisture and oxygen away from printed materials. It significantly prevents ink degradation. Additionally, films incorporating UV inhibitors resist most ultraviolet radiation, slowing fading rates.

- Visual enhancement: High-gloss or matte finishes make lamination film look premium. Plus, it’s cost-effective when applied correctly.

- Operational convenience: Lamination film is easy to use. Just activate the machine and operate it well. Minimal manual steps are needed.

Which is superior – hot or cold lamination film?

Neither type is inherently better; their distinct properties suit different applications.

Hot lamination film incorporates heat-activated adhesives, offering superior moisture resistance. It performs notably better than cold lamination film in damp or cold environments. Hot lamination film also demonstrates marginally superior anti-UV performance. Regarding cost, cold lamination film offers lower equipment expenditure for small-scale applications. For large-scale processing, hot lamination film is more suitable. For heat-sensitive photographs or vintage film, cold lamination film is the only option to prevent damage.

So, neither option is better. The important thing is to choose the right film for your needs.

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351