What Is Packaging Foam?

Foam packaging is a kind of packaging material that can protect products and goods during transportation. It prevents product goods from being crushed and shattered. Packaging foam also has barrier properties, chemical resistance, and can protect products from damage in many environments. Packaging foam is used in a wide range of applications and can be specially customized in shape and size according to the needs and purpose. It is usually made from polystyrene, polyurethane, or expanded polyethylene foam. It has excellent shock-absorbing properties. Prior to shipping, the packaging foam is usually cut to fit the shape of the product. This allows for a better fit and prevents shifting during transportation. Packaging foam is an Efficient packaging solution that is very reliable.

Why Choose Foam Packaging Material?

Packaging foam is strong, durable, and lightweight. It is excellent for protecting fragile items, medical equipment, electronics, and damaged products from damage. Foam packaging can also be cut to fit the shape of the product. Make the foam packaging fit the product more closely.

Excellent protection and performance: foam packaging can provide the necessary support. Provide gentle cushioning and maximum protection for fragile items. Foam packaging can also absorb the impact of falling. It can be customized for different application needs, providing customized protection. Foam packaging can last for many years, continuing to provide protection for products. It absorbs sound on impact and is very quiet. It is also very lightweight.

Cost-effective: foam packaging uses less material for better protection. Products can be adequately protected with very little foam packaging. If damage occurs to the product goods, the cost to the business is more likely to be greater. Compared with other packaging materials (paper), foam packaging is more cost-effective.

Sustainability: Foam is more sustainable in terms of carbon emissions from manufacturing to transportation. The production of polyethylene foam consumes less energy than the production of non-plastic packaging materials. The production of foam packaging also has a lower environmental impact. It can also be recycled.

What Are the Benefits of Packaging Foam?

Packaging foam has many advantages. It can give very good protection to the product. It also has excellent cushioning ability to absorb impacts. You can learn more about its advantages in more detail below.

Soft: Foam packaging material is very soft. It is very suitable for wrapping fragile items. It prevents these items from being damaged due to shaking during transportation. The soft packaging material also prevents scratches, chips, or other types of damage. Large items like furniture are well-suited for foam packaging.

Recyclable: Packaging foam is mainly made from low-density polyethylene. So it is a renewable material. It is very important for companies that are pursuing green and sustainable development.

Anti-static: Part of the foam packaging also has anti-static properties. Packing electronic products with it will protect the electronic products. Let the electronic products be protected from static electricity damage and physical damage.

Lightweight design: The packaging foam material is very light. It can greatly reduce transportation costs. The effect of protecting the products is also very good.

High flexibility: The packaging foam can be customized according to the size of the product. It can fit the shape of the product very well, saving space and protecting the product. Very adaptable

What are the applications of foam packaging?

Foam packaging has a very wide range of applications and is used in various fields.

Electronic products: precise electronic products are fragile and very sensitive to static electricity. PE foam and anti-static foam have an excellent effect on static electricity shielding. And it can provide cushioning against shock. It is widely used in the packaging of electronic products such as circuit boards and laptops.

Medical Devices: Medical devices require a sterile and moisture-proof environment, and collisions need to be avoided during transportation. Polyurethane (PU) foam has a unique open-cell structure. It allows free flow of gases and enhances breathability. It allows Tight conformity to medical devices. It is commonly used to package surgical instruments and diagnostic equipment.

Automotive and aviation parts: Automotive and aviation parts are usually very heavy. The performance requirements for packaging materials are very high. Silicone foam has excellent shock absorption and thermal stability. It also has chemical resistance and flame retardancy. It can be insulated in engine compartments or high altitude environments.

Furniture and large irregular items: Furniture is large, and the surface is easily scratched. PE foam has excellent cushioning protection and can also be cut into any shape. It fits well with packaged products. It is also convenient for printing a brand. It can be used to pack lamps, sofas, etc.

Types of Foam Packaging Materials

There are many types of foam packaging. Understanding these different types will allow you to make a better choice of foam packaging.

Anti-Static ESD Foam: Made from specially formulated foam. It has anti-static properties. Can protect electronic products that are sensitive to electrostatic discharge from being affected. Usually used in combination with other packaging materials.

Expanded Polystyrene (EPS): A very affordable foam packaging material. It has very good durability and insulation properties. But it is not rigid enough. It is commonly used for cushion support. It is a lightweight, rigid foam. It is commonly used for packaging electronics, appliances and food.

Polyurethane (PU): PU foam packaging is perfect for packaging lightweight and fragile products. It is just very flexible. It can wrap products very easily. Cushioning performance is excellent. It can protect the product very well during transportation.

Polyethylene (PE): PE foam packaging has excellent moisture resistance. The durability is very good, and the weight is very light. It can block water, chemicals, and mold. Great for wrapping produce. It has good rigidity as well. It can hold up well.

Insulating Foam: Insulating foam is a packaging material that insulates. It reduces heat transfer and blocks air. It is often used to seal floors and ceilings. It prevents air movement. It can make a building cooler in the summer and warmer in the winter.

How to Choose the Right Foam Packaging Material?

Foam packaging is very important for the protection of your products. If you choose the wrong type that is not suitable, the risk of product damage will be very high. Here we learn together how to choose the right foam packaging.

- Product characteristics:

When choosing foam packaging, we have to consider the characteristics of the product. Including the size and weight of the product, and whether the product is fragile. Large, heavy product goods need stronger protection. Heavy items are not suitable for expanded polystyrene foam because it is more likely to break. Fragile items need Tight and secure wrapping that conforms to the product. - Transportation conditions:

Whether the product shipment can be exposed to moisture, extreme temperatures, or shaking for long periods of time. Some foam packaging (like polystyrene) is suited to extreme temperatures and can protect the product from temperature damage. These special transportation conditions are very important to the choice of foam packaging. Options include truck, air, boat, or drone transportation. - Cost budget:

The cost budget for different types of foam packaging is different. However, choosing the right and excellent foam packaging can prevent damage to your items. Reduce the risk of returns and damage claims. - Sustainability:

There are disposable foams and reusable foams. For businesses seeking sustainability, they can choose the second one.

Different types of foam packaging are suitable for scenarios:

- Liners: EPS liners or PE liners for apparel and electronics.

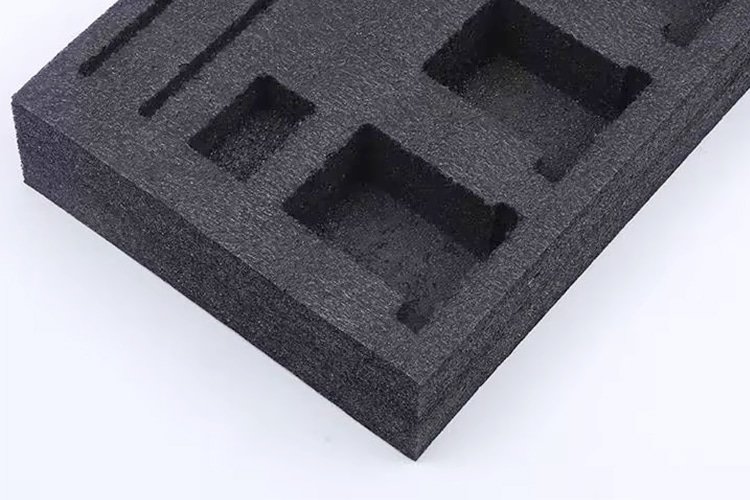

- Custom Case Foam Insert:It provides Tight conformity to the product and can hold the product well. Suitable for packaging fragile or delicate products. Automotive parts, photographic and video equipment, and irregularly shaped products.

- Corner & Edge Protectors: Suitable for protecting corners and edges of fragile products.For example, edge protectors for photo frames, corner protectors for furniture, tables, and chairs.

- Foam Wrap Rolls and Sheets:It has excellent shock-absorbing properties and can protect the product well, preventing the surface from being scratched. Its flexibility and moisture resistance are also excellent. Suitable for protecting electronic products, wrapping products, and crates or lining boxes.

- Foam Blocks: can be used to wrap products and fill the space inside the box. Ensure that the product does not shake. Suitable for refrigeration and insulation of corrosive goods.Filling the container space. Protect product corners and provide shock absorption. Cushioning heavy products during transportation.

FAQ

What is the difference between PU and PE foam?

What is the difference between PU foam and PE foam?

PU foam is a polymer foam that is made from polyurethane. It includes both rigid and flexible foam. It has excellent cushioning properties. It can be used for furniture and bedding. It also has excellent insulation properties. It can be used in the construction industry to keep buildings warm.

PE foam is also called polyethylene foam. It is a lightweight foam. It has a unique closed-cell structure. It has excellent durability and chemical resistance. It can be used for fragile items and car parts protection. It is also more cost-effective than PU foam.

Related Products

No posts

Related Blog

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351