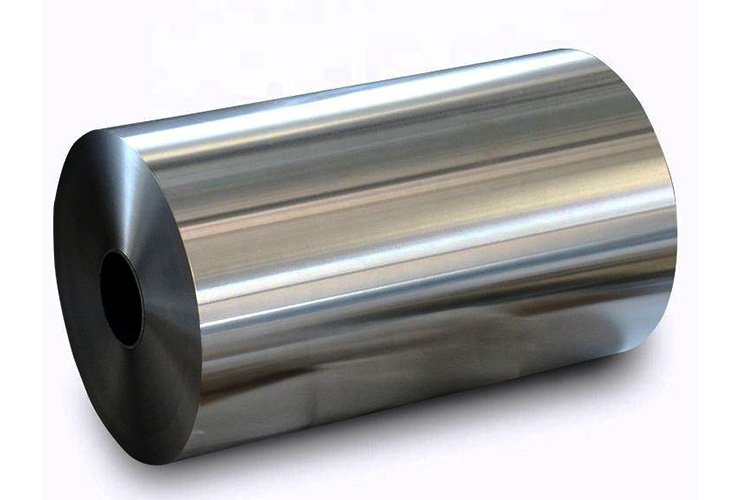

What is metallized PET film?

Metallized Film is also known as Metallized Polyester Film or aluminized PET Film. It undergoes special treatment during the manufacturing process. A metallic aluminum coating is deposited on the surface of the film. It has a very high Glossiness surface with unique optical properties. It is suitable for reflective applications. It also has excellent heat resistance, close to 280°F. It has applications in many fields. Food packaging, insulation, printing, lighting, etc.

How is metallized PET film manufactured?

PET Metallized Film is made by a unique physical vapor deposition process. The metal deposited is usually aluminum. However, sometimes the metal chromium is also used.

The PET film is first cleaned. This is accomplished by removing any dirt, dust, or contaminants that would interfere with the adhesion of the metal layer. It is usually cleaned and treated with specific chemicals.

In the second step, the metal is then allowed to heat and evaporate in a vacuum environment, before being attached to the film through condensation. The thickness of this coating is about 0.45 microns. And the stability of the coating is outstanding. It will not lose color or discoloration over time.

Finally, the surface of the PET Metallized Film is then coated with a protective layer. It further improves the durability and oxidation resistance of the film. It also enhances the overall Film Performance.

Advantages and Disadvantages of Metallized PET Film

Metallized PET film features a unique structure. It offers numerous advantages in practical applications. However, metallized PET film also has certain limitations. Common advantages and disadvantages are as follows:

Advantages: Metallized PET film offers excellent barrier properties. It effectively blocks water vapor and oxygen, achieving an OTR (Oxygen Transmission Rate) of 0.02–0.12 cc/100 sq in/24 hrs. Its oxygen barrier performance is outstanding. Additionally, metallized PET film boasts high strength and stability. The metal coating enhances reflectivity, significantly improving the visual appeal of retail products, cosmetics, or food packaging.

Disadvantages: When used as a metallized label, metallized PET film adheres poorly to product surfaces. It must be applied to sealable packaging films. Recycling metallized PET film poses challenges due to its inherent complexity. Additionally, the film’s sharp edges may cause scratches or abrasions during transportation or packaging.

Characteristics of PET Metallized Film

The unique production process of PET Metallized Film gives it a very wide range of outstanding Film Performance.

Outstanding Barrier: PET Metallized Film has excellent barrier ability. It provides a good barrier against oxygen, moisture, and light. Helps protect sensitive products such as electronics, food, and pharmaceuticals. Extends shelf life.

Mechanical Properties: PET Metallized Film has excellent mechanical properties. It is a very reliable packaging material. It has very good tensile strength. Dimensional stability and tear resistance are also excellent. It can protect the packaging products very well.

Strong heat sealability: PET Metallized Film has excellent Heat sealability. It can effectively insulate against heat and heat reflection. Its Heat sealability is close to 280℉. It is widely used in insulation, reflective materials, and solar control films. It can effectively control temperature and improve energy efficiency.

High reflectivity: The metallic surface of PET Metallized Film makes it very reflective. It can reflect more light into the human eye. It can effectively improve visibility and attract consumers’ attention. It is widely used in decoration, labeling, and other scenes.

Applications of PET Metallized Film

PET Metallized Film Performance is excellent and has applications in many fields.

Flexible food packaging: PET Metallized Film is commonly used to package snacks, candy, popcorn, etc. It has excellent barrier performance and can be good for extending the shelf life. And with Glossiness, it can attract consumers well.

Electronics industry: PET Metallized Film has high reflectivity and low permeability characteristics. This makes it commonly used in Electromagnetic Shielding and flexible circuit printing. In flexible circuit printing, the film can provide a flexible and lightweight substrate for electronic components. It will also be used in capacitors, reflective displays, and more.

It can serve the purpose of shielding very well. Prevent interference and maintain signal integrity.

Automotive industry: the excellent reflective ability of the surface of PET Metallized Film. It is commonly used in automobile reflective insulation and decoration. Make the car more attractive and have a quality appearance.

Aerospace Applications: PET Metallized Film can be used in astronauts’ suits, where it reflects heat radiation. It can provide warmth to astronauts. It is also used in firefighters’ fire suits. It can protect the fire suit from the large amount of heat released by the fire. It can also be used to protect the body temperature of injured people.

Effective UV Protection: The surface of metallized PET film exhibits strong reflective properties. When applied in packaging scenarios, it creates a highly eye-catching effect. Simultaneously, the metallic coating serves as an effective barrier against electromagnetic radiation. Metallized PET film can also be used to block light waves, effectively reflecting infrared and ultraviolet light. Aluminum-coated PET film delivers the most outstanding reflective performance. Compared to other metallized films, the reflectivity of aluminum coatings remains consistent across all wavelengths.

Barrier Properties of Metallized PET Film

We all know PET film offers excellent barrier properties. But how do we compare barrier performance? Currently, two parameters measure barrier performance: OTR (oxygen transmission rate) and WVTR (water vapor transmission rate). Lower values indicate superior barrier properties. Metallized PET film achieves OTR values of 0.02–0.12 cc/100 in²/24 hours. Its WVTR is below 1.1 g/m²/24 hours. Within the industry, films with OTR <1 cc/100 in²/24 hours and WVTR below 16–20 g/m²/24 hours are classified as high-barrier films. Metallized PET film significantly exceeds these standards. Therefore, metallized PET film forms a highly effective barrier.

BESTYPACK

Bestypack specializes in the production, manufacturing, and development of PET Metallized Film. It is your first choice for customized PET Metallized Film. Our PET Metallized Film is industry-leading in functionality and sustainability. They can be customized to meet your brand’s unique needs. Providing you with outstanding protective performance and a striking appearance. Our PET Metallized Film solutions combine durability, flexibility, and environmental friendliness for a variety of industries.

FAQ

What are the types of metallized films?

There are many types of Metallized Film, each with unique properties. They can fulfill different needs. Here are some common Metallized Films.

- PET Metallized Film: has excellent barrier, reflective, and mechanical properties. Widely used in flexible packaging, insulation applications, and lamination.

- PE Metallized Film: Excellent moisture barrier performance and lower cost. Commonly used in casual food packaging and agricultural scenarios.

- Metallized Aluminum Film: Has a thin layer of metallic aluminum on the surface. It has superior barrier properties, thermal insulation, and reflectivity.

- PP Metallized Film: Heat sealing, tensile strength, and excellent moisture resistance. Mainly used in decorative applications and food packaging.

What is the difference between DTF and PET film?

PET film refers to polyester film, while DTF is a unique printing method. DTF involves printing designs onto clothing, hats, or other materials using a heat press machine. It is commonly printed on textiles like canvas, knits, and polyester. PET film, however, is a protective film made from polyester material. It is primarily used for packaging goods, food protection, electronics, consumer products, and similar items. Their applications and characteristics differ significantly. PET film offers superior protective properties. DTF film excels in heat resistance and transparency. Most importantly, it delivers the best printing effects and print quality.

What is metallized PET film used for in food packaging?

Metallized PET film finds extensive application in food packaging due to its numerous suitable characteristics.

- Superior Barrier Properties: Metallized PET film offers excellent barrier properties. It effectively blocks moisture vapor and oxygen while possessing reflective qualities. Most foods face challenges like oxidation, moisture exposure, and UV light exposure. Using metallized PET film for food packaging effectively addresses these issues.

- Visual Appeal: Metallized PET film features a metallic sheen. Using it for food packaging significantly enhances the visual appeal of the product.

- High cost-effectiveness: Metallized PET film offers outstanding cost efficiency. Compared to traditional packaging materials, it has lower material costs. Additionally, its lightweight nature reduces transportation expenses.

Metallized PET film is commonly used for packaging foods, candies, snacks, refrigerated items, and products with extended shelf lives.

Is PET film safe?

PET film is manufactured from polyethylene terephthalate (PET), an inert material that is non-toxic, odorless, and safe. Consequently, PET film complies with FDA food safety standards and is suitable for food packaging applications. While concerns about EA leaching from PET plastics into water existed in the past, PET film does not face this issue. Furthermore, PET film is one of the most recyclable plastics, enabling repeated reuse.

Hello, customers

My name is Jack Yu. I am the Business Manager at BestY Pack Plastic Products. My areas of expertise include film packaging, cold chain transportation packaging, and shrink products. Additionally, our factory manufactures protective gloves, and I can provide you with professional solutions to help you increase your market share and enhance consumer trust.

Email: ᅠjackyu@bestypack.com

Tel: +86 18368319351