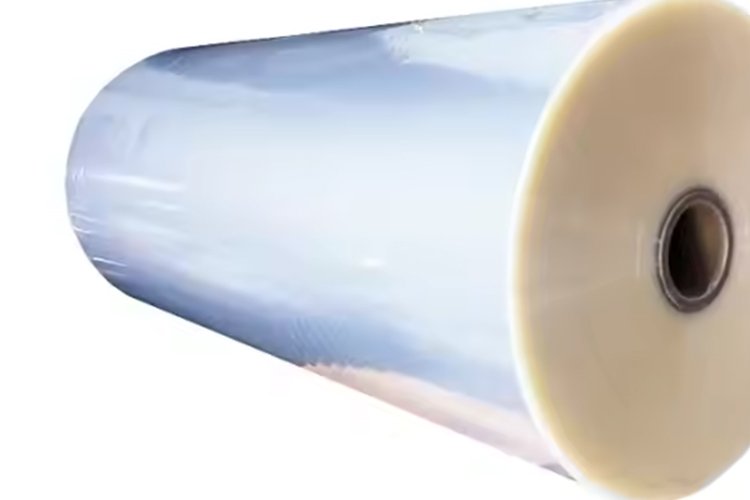

Retort CPP Film Heat Resistant

CPP retort film is a high-temperature and high-pressure-resistant polypropylene film. It is a cast film. It has good sealing properties and is safe and non-toxic. It has gained widespread use in the retort pouch market. You can also use it for food preservation and high-temperature sterilization. It can significantly prolong the shelf life of food. Our CPP film has a simple production design. This saves costs and maintains high quality. Choosing our CPP retort film is a wise choice.

We look forward to working with you! We are a professional manufacturer of CPP Retort film.

- High stability, suitable for high-temperature and high-pressure sterilisation

- Excellent sealing performance, superior freshness retention

- Streamlined design, reducing costs

- Safe, non-toxic, and recyclable, suitable for direct contact with food

Product Details of descriptions

CPP retort film is a cast polypropylene film. It has excellent stability, high temperature resistance, and high pressure resistance. It can even be used in pressure cookers. Good sealing and barrier properties. It can block water, oxygen, and contaminants. It is ideal for high-temperature sterilisation. Excellent heat sealability ensures that bacteria cannot enter the packaging after sterilisation. Transparent appearance, allowing the product to be clearly displayed. Commonly used in vacuum packaging for food.

This film is typically used in combination with other materials, such as aluminium foil or other plastics, to enhance packaging functionality and puncture resistance. Our film design is tailored to the needs of the CPP retort film market, featuring a streamlined design that significantly reduces costs while maintaining film quality. It has obtained multiple international certifications, including ISO 9001 certification and FDA approval, and is environmentally friendly and recyclable.

As a leading film manufacturer in China, we offer customised production tailored to your specific requirements. We welcome you to contact us for customised production!

Parameter

| Parameter | Specification |

|---|---|

| Length | 30 ~ 2000 mm, Customizable |

| Thickness | 40 ~ 120 um, Customizable |

| Width | 20 ~ 2000 mm, Customizable |

| Core Diameter | 3″ / 6″, Customizable |

| Color | Transparent |

| Lamination | Typically with Alu Foil / Other Plastic Films |

Product Features

| Property | Specification | Property | Specification |

|---|---|---|---|

| Density (g/cm³) | 0.90 | Breaking Elongation, MD/TD (%) | ≥900 / ≥1000 |

| Haze (%) | 5 ~ 15 | Heat Seal Strength (g/25mm) | 3500 ~ 4000 |

| Tensile Strength, MD/TD (kg/cm²) | ≥500 / ≥300 | Coefficient of Friction | 0.50 ± 0.05 |

| Wetting Tension (mN/m) | 40 | Payment Terms | L/C, T/T, D/P, D/A, WU, MG, PayPal, XTransfer, O/A, Bank Guarantee |

| Shipping Method | Palletized Transport | Shipping Port | Shanghai Port, Guangzhou Port, Hong Kong Port |

advantages

- High-temperature resistance: Users can utilize it for high-pressure and high-temperature sterilization.

- Strong barrier properties: Can isolate air and oxygen, which extend shelf life.

- Good heat sealability: can maintain a tight seal.

- High flexibility: Manufacturers can mold it to fit product shapes.

- Can be used together: Often paired with gold foil and different plastics.

- Production technology innovation: smooth machine processing and efficient production.

- Low cost: Simplified design, reduced costs, and uncompromising quality.

- Safe and non-toxic: Can come into direct contact with food.

- Recyclable: Environmentally friendly and biodegradable.

- Easy to open: Smooth and easy to open packaging.

Application

- Vacuum food packaging may directly touch food and boast superb preservation qualities.

- CPP retort bags: Excellent stability, high temperature, and high-pressure resistance.

- High-temperature sterilization packaging: Good sealing properties effectively isolate external contaminants after sealing and sterilization.

- Seasoning packet packaging: Prevents liquid leakage and extends shelf life.