BOPET Film manufacturer

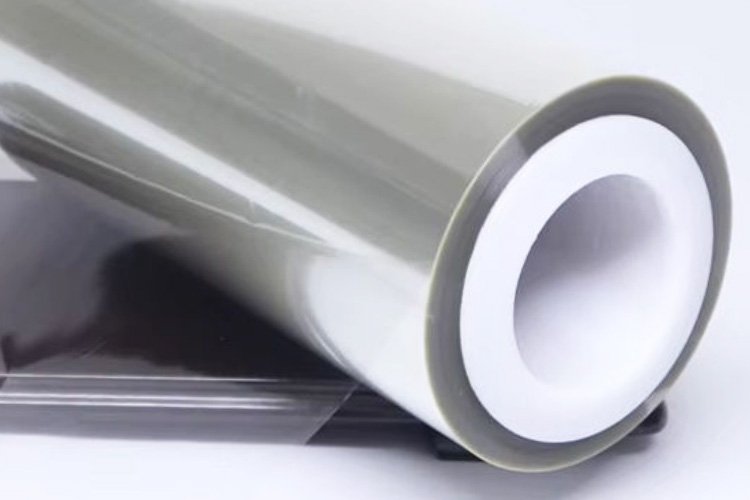

BOPET film is a polyester film produced through a biaxial stretching process. It is an exceptionally stable film. It supports diverse processing treatments, including corona treatment, release coating, and metallization. It offers excellent stretchability, stability, high transparency, and insulation properties. It provides significant freshness preservation, protection, and aesthetic enhancement for packaging. We are a professional BOPET film manufacturer.

Related product

We offer a wide range of BOPET film styles and colors for your selection.

We offer over 26 varieties of BOPET film and also provide bespoke solutions; Contact us for further details.

Adopting cutting-edge technology to ensure efficient and stable production.

Rigorous quality inspections to guarantee superior product performance.

Optimized production processes for high-value, cost-effective solutions.

Diverse processing capabilities to meet unique customer requirements.

Top BOPET film Manufacturer and Suppliers in China

We are specialists in BOPET film. Please let us know your requirements, and we shall commence our collaboration.

Customized BOPET Film Solutions

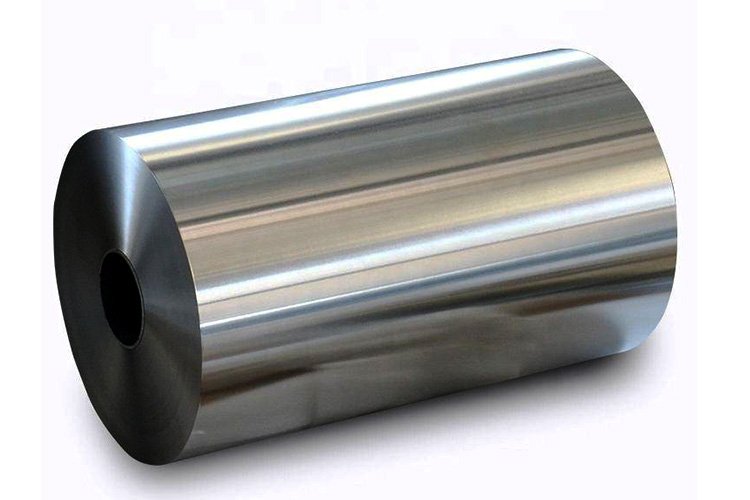

BestY Pack provides custom services, such as metallized films, holographic films, twist films, and thermal transfer films, to fit your needs! Gold, silver, and transparent frosted finishes elevate your packaging with modern flair. Our BOPET films undergo rigorous quality control to safeguard your products. Eco-friendly and recyclable, they reduce carbon emissions. Try BestYPack’s BOPET films today and upgrade to superior packaging!

BOPET film compared to other films:

- Tensile strength is 9 times that of PE film.

- High light transmittance with a reflectance of up to 99%.

- Strong electrical insulation meets Class E insulation material standards.

- Temperature resistance range: -70°C to 150°C. This material is Class B heat-resistant.

- More affordable and cost-effective.

- Barrier properties: Medium-high level.

- UV resistance: Medium-high level.

- Printability: Medium-high level, clear, and durable.

- Processing options: Highly versatile.

BOPET film has a wide range of applications

BOPET film boasts outstanding properties across many dimensions, finding applications in diverse fields. It covers a wide range, from daily food packaging to aerospace uses and scientific studies.

- Flexible Packaging:

BOPET film is ubiquitous in flexible food packaging, particularly prevalent in the food sector. Its great barrier properties and airtightness keep food fresh, preserving its original taste. With exceptional heat resistance, it can even withstand direct microwave heating. Metallized BOPET film further enhances these capabilities. Common applications include yogurt lids, potato chip packaging, frozen meals, and can laminates. - Protective & Decorative Films:

BOPET film offers strong durability and great optical clarity. This high transparency ensures excellent visibility. This makes it an ideal choice for high-visibility protective films. It facilitates multi-layer printing, flexible layering, and delivers crisp, convenient results. Used as protective films for fine art, they keep colors bright and guard against damage and scratches. They safeguard photographs, slowly fading to keep memories vivid. Protecting paper documents becomes effortless. - Insulation Film:

Its insulating properties make BOPET uniquely versatile. It offers excellent electrical insulation, light insulation, thermal insulation, and radiation resistance. It is widely applied in aerospace applications, wilderness survival, and firefighting. Examples include thermal insulation for spacesuits, emergency cold-weather blankets for wilderness survival, and protective gear for firefighters. - Solar Energy, Aviation, and Marine:

With reflectivity reaching up to 99%, it excels in light-reflective applications. These include solar photovoltaic panels, total solar eclipse viewers, solar sails, and space solar sails.

Beyond these, BOPET finds use in scientific research and electronic/acoustic fields. Examples include banjo and drum heads, as well as tape and floppy disk substrates.

When is BOPET film more suitable for use?

- Packaging products with moisture-proof and strict airtightness requirements.

- Strong demand for UV resistance.

- Product surfaces requiring high-strength protection.

- High reflectivity and high glossiness requirements.

- High folding performance requirements.

Why choose our BOPET film?

We are a major BOPET film manufacturer in China. We have a lot of production experience. Over the years, we’ve built strong partnerships and received great feedback. Our film production uses an assembly line with imported machines. This helps us achieve a uniform thickness. We keep pace with the times and are committed to pursuing innovation. Our factory management is organized. All BOPET film types are categorized and stored in clean areas.

The Advantages of Our BOPET Film

- Dustproof and moisture-proof, freshness-preserving

- Can be folded many times without tearing.

- Customizable production with many styles is available.

- Extremely high tensile strength

What are the popular styles of BOPET film?

We utilize our advanced production and processing technologies to diversify film applications. This includes corona-treated films, release films, twisted films, metallized films, shrink films, thermal transfer films, and holographic films. Simply share your requirements with us, and our experts will design a customized solution tailored to your needs.

Differences Between Various BOPET Films

Here is the table formatted in English with the “Features” and “Applications” content shortened by approximately half, as per your previous request:

| Type | Thickness (Customizable) | Features | Applications |

|---|---|---|---|

| Corona Treated PET Film | 5~300um | Strong surface tension; High ink adhesion; Works with coatings, adhesives; Strong barrier, moisture-proof | Soft packaging: Food, medical, daily chemicals; Luxury gift boxes; Brand logo packaging; Book covers; Industrial release |

| PET Release Films (Silicone Coating) | 15~300um (Classic: 23/30/36/50) | Easy release, strong anti-stick; Durable, tear-resistant; Stable, corrosion/heat-resistant | Release applications: Pressure-sensitive labels, tapes, adhesives, asphalt processing, electronics |

| Clear PET Film (Transparent Film) | 15~500um | High transparency; Durable, tear-resistant; Strong ink adhesion; Glossy/matte; Corrosion/heat-resistant | Industrial processing; Protective films: Glass, automotive; Optical: Photovoltaic panels; Adhesive labels |

| Matte PET Film (Exquisite Matte Film) | 0.7~400um | Reduces glare; Durable, tear-resistant; Strong ink adhesion; Glossy/matte; Corrosion/heat-resistant | Soft packaging: Clothing bags; Heat transfer films; Coating materials; High-quality matte printing; Custom logo packaging |

| PET Heat Transfer Film (DTF Transfer Film) | 30~80um | Supports DTF printing; Cold/hot peel; High gloss, aesthetic printing | Clothing pattern printing; Fabric banner printing |

| Holographic PET Film (Wide Variety) | 14~25um | 3D/rainbow effect; Heat-resistant, waterproof; High gloss, eye-catching | Packaging: Cigarette boxes, gift boxes; Powder products: Coffee, protein powder; Snack/tea bags; 3D stickers; Anti-counterfeit labels |

| PETG Shrink Film | 35~45um (Classic: 40) | High shrinkage; Tough, break-resistant; Works with various machines; High transparency | Vacuum packaging: Roasted chicken, smoked meat; Beverage labels: Cola, water; Book covers; Daily chemicals: Shower gel sets |

| Metalized PET Film | 6~53um | High gloss, metallized surface; High reflectivity; Strong sealing | Food packaging: Candies, chocolate; Insulation: Emergency blankets, spacesuits; Reflective lighting: Flashlights |

| PET Twist Film | 10~33um | Strong folding/twisting stability; Anti-static, dust-resistant; Wear-resistant, durable | Snack packaging: Chocolate, toffee, beef jerky, lollipops |

Production Process

Contact Us

BestY Pack Industries Ltd. is a specialized manufacturer of packaging materials. We offer shrink film, flexible packaging, wrap-around film, tapes, insulation and shipping packaging. We offer OEM and ODM customized production. We are pleased to establish business relationship with you. We provide reliable solutions for you.